Why Manufacturers Need Modern Security Solutions for Safe, Efficient Operations

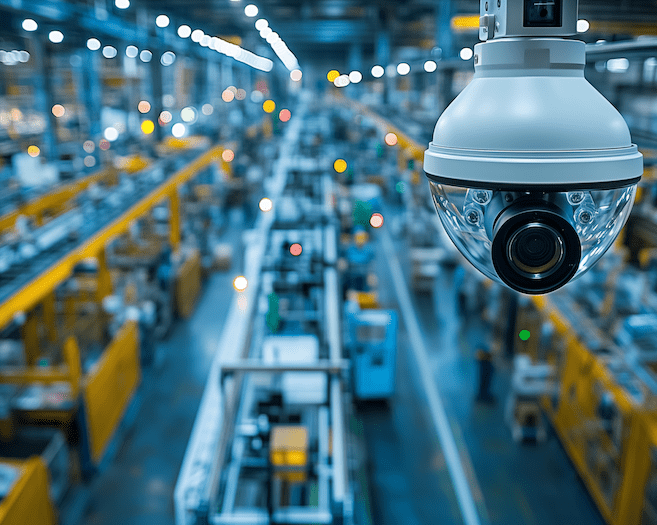

In today’s industrial landscape, manufacturing environments face unique security challenges that go beyond basic surveillance. To stay competitive and safe, manufacturers must adopt advanced security solutions like alarms, cameras, access control systems, and air quality sensors. These technologies not only enhance safety and protect assets but also improve productivity, compliance, and incident response times.

As an IT services provider, we design and implement integrated security solutions that align with the unique requirements of manufacturing. Here, we discuss why embracing these modern solutions is essential for future-ready manufacturing.

Enhanced Operational Efficiency

Real-time monitoring capabilities transform day-to-day operations, driving more informed and responsive decision-making. Modern security solutions with AI-driven insights allow manufacturing teams to:

- Monitor Floor Operations: Continuous video monitoring enables better management of workflows, prompt identification of bottlenecks, and faster intervention when issues arise.

- Optimize Workflow and Layout: Features like heat maps and automated tracking can reveal areas of high traffic and inefficiencies, allowing manufacturers to reorganize spaces and minimize wasted movement.

- Ensure Supply Chain Integrity: Secure, technology-enabled loading docks and controlled access to inventory can protect against losses and ensure smooth, verified supply chain activities.

An integrated platform consolidates these insights, making it simple to monitor and optimize operations across multiple sites in real time.

Strengthened Workplace Safety and Compliance

Manufacturing facilities involve heavy machinery, hazardous materials, and dynamic environments, all of which increase safety challenges. Security technologies like advanced cameras, panic buttons, and environmental sensors contribute to a safer workplace by:

- Preventing Incidents Proactively: AI-powered cameras can detect potential safety risks, such as workers in restricted zones or unsafe behaviors, and alert teams to intervene before incidents occur.

- Facilitating Incident Investigation: High-resolution footage assists in quickly investigating incidents, improving safety training, and identifying areas for improvement based on real-world scenarios.

- Monitoring Health Hazards with Air Quality Sensors: Sensors that track pollutants, dust, temperature, and humidity provide real-time alerts, enabling faster response to unsafe conditions and helping manufacturers meet OSHA and environmental compliance requirements.

These tools enable manufacturers to create a safety-first culture and maintain compliance with regulatory standards by generating and storing thorough safety records.

Improved Site Security Against Theft and Unauthorized Access

Manufacturing facilities hold valuable assets, often spread over large areas, making them vulnerable to theft and unauthorized entry. Modern security products offer multi-layered protection:

- Controlled Access to Sensitive Areas: Access control systems restrict entry to critical zones, helping safeguard production areas, storage facilities, and IT rooms. They also log entry data, ensuring that manufacturers can track and verify access.

- Intrusion Detection and Response: Sensors, alarms, and cameras equipped with AI can detect unauthorized access, while remote monitoring allows for prompt action, such as notifying law enforcement or on-site security.

- Visitor Management and Monitoring: Digital visitor logs and badge printing create a secure, seamless visitor experience while enabling better tracking of individuals on-site, an essential component of both security and compliance.

An integrated approach to security unifies these elements, making it simpler to protect assets, manage multiple locations, and respond effectively to security threats.

Liability Protection and Compliance

Regulatory compliance and liability protection are non-negotiables in manufacturing, where safety incidents, quality control issues, and data security are significant concerns. With a unified security solution, manufacturers can:

- Protect Data and Meet Compliance Standards: Digital storage and management of footage make it easier to maintain detailed records for audits and investigations.

- Generate and Share Incident Reports Easily: Centralized, searchable footage enables quick report generation, critical for compliance with standards from OSHA to environmental and quality control bodies.

- Scale Securely Across Sites: A centralized platform offers ease of expansion and user access control, simplifying compliance across locations and minimizing data security risks.

Environmental Monitoring for Product Quality and Safety

Environmental conditions are critical to both product quality and worker health. By monitoring factors like temperature, humidity, and air quality, modern security solutions enable proactive management of these variables:

- Continuous Air Quality Monitoring: Real-time alerts allow teams to address poor air conditions promptly, helping to maintain worker health and reduce production risks due to contamination.

- Automated Environmental Controls: Integrations with HVAC and filtration systems can respond to real-time air quality data, automatically optimizing for safe, comfortable working conditions.

- Enhanced Quality Control and Compliance: Environmental sensors support the consistent quality necessary for manufacturing standards and customer expectations, ultimately strengthening brand reputation and product reliability.

Conclusion

In today’s competitive manufacturing environment, a comprehensive security strategy is about more than just protection—it’s a business enabler. The right security solutions can drive operational efficiency, enhance safety, and ensure compliance, all while safeguarding assets. By investing in modern, integrated security platforms, manufacturers position themselves for growth, resilience, and leadership in the industry.

If you’re interested in learning more about the innovative solutions ANM and Verkada are delivering to meet these needs in modern manufacturing, let’s talk!

- Enhanced Operational Efficiency

Real-time monitoring capabilities transform day-to-day operations, driving more informed and responsive decision-making. Modern security solutions with AI-driven insights allow manufacturing teams to:

- Monitor Floor Operations: Continuous video monitoring enables better management of workflows, prompt identification of bottlenecks, and faster intervention when issues arise.

- Optimize Workflow and Layout: Features like heat maps and automated tracking can reveal areas of high traffic and inefficiencies, allowing manufacturers to reorganize spaces and minimize wasted movement.

- Ensure Supply Chain Integrity: Secure, technology-enabled loading docks and controlled access to inventory can protect against losses and ensure smooth, verified supply chain activities.

An integrated platform consolidates these insights, making it simple to monitor and optimize operations across multiple sites in real time.

- Strengthened Workplace Safety and Compliance

Manufacturing facilities involve heavy machinery, hazardous materials, and dynamic environments, all of which increase safety challenges. Security technologies like advanced cameras, panic buttons, and environmental sensors contribute to a safer workplace by:

- Preventing Incidents Proactively: AI-powered cameras can detect potential safety risks, such as workers in restricted zones or unsafe behaviors, and alert teams to intervene before incidents occur.

- Facilitating Incident Investigation: High-resolution footage assists in quickly investigating incidents, improving safety training, and identifying areas for improvement based on real-world scenarios.

- Monitoring Health Hazards with Air Quality Sensors: Sensors that track pollutants, dust, temperature, and humidity provide real-time alerts, enabling faster response to unsafe conditions and helping manufacturers meet OSHA and environmental compliance requirements.

These tools enable manufacturers to create a safety-first culture and maintain compliance with regulatory standards by generating and storing thorough safety records.

- Improved Site Security Against Theft and Unauthorized Access

Manufacturing facilities hold valuable assets, often spread over large areas, making them vulnerable to theft and unauthorized entry. Modern security products offer multi-layered protection:

- Controlled Access to Sensitive Areas: Access control systems restrict entry to critical zones, helping safeguard production areas, storage facilities, and IT rooms. They also log entry data, ensuring that manufacturers can track and verify access.

- Intrusion Detection and Response: Sensors, alarms, and cameras equipped with AI can detect unauthorized access, while remote monitoring allows for prompt action, such as notifying law enforcement or on-site security.

- Visitor Management and Monitoring: Digital visitor logs and badge printing create a secure, seamless visitor experience while enabling better tracking of individuals on-site, an essential component of both security and compliance.

An integrated approach to security unifies these elements, making it simpler to protect assets, manage multiple locations, and respond effectively to security threats.

- Liability Protection and Compliance

Regulatory compliance and liability protection are non-negotiables in manufacturing, where safety incidents, quality control issues, and data security are significant concerns. With a unified security solution, manufacturers can:

- Protect Data and Meet Compliance Standards: Digital storage and management of footage make it easier to maintain detailed records for audits and investigations.

- Generate and Share Incident Reports Easily: Centralized, searchable footage enables quick report generation, critical for compliance with standards from OSHA to environmental and quality control bodies.

- Scale Securely Across Sites: A centralized platform offers ease of expansion and user access control, simplifying compliance across locations and minimizing data security risks.

- Environmental Monitoring for Product Quality and Safety

Environmental conditions are critical to both product quality and worker health. By monitoring factors like temperature, humidity, and air quality, modern security solutions enable proactive management of these variables:

- Continuous Air Quality Monitoring: Real-time alerts allow teams to address poor air conditions promptly, helping to maintain worker health and reduce production risks due to contamination.

- Automated Environmental Controls: Integrations with HVAC and filtration systems can respond to real-time air quality data, automatically optimizing for safe, comfortable working conditions.

- Enhanced Quality Control and Compliance: Environmental sensors support the consistent quality necessary for manufacturing standards and customer expectations, ultimately strengthening brand reputation and product reliability.

Conclusion

In today’s competitive manufacturing environment, a comprehensive security strategy is about more than just protection—it’s a business enabler. The right security solutions can drive operational efficiency, enhance safety, and ensure compliance, all while safeguarding assets. By investing in modern, integrated security platforms, manufacturers position themselves for growth, resilience, and leadership in the industry.

If you’re interested in learning more about the innovative solutions ANM and Verkada are delivering to meet these needs in modern manufacturing, let’s talk!

7-Step Process in Effective Tabletop Exercises

Proactive preparation is paramount for organizations seeking to safeguard their digital assets and mitigate potential risks. One effective strategy for enhancing cyber resilience is conducting tabletop exercises, which simulate real-world cyber incidents in a...

Beyond the Buzzwords: The Real Pain Points of Data Security for Businesses

Today businesses of all sizes grapple with the relentless task of safeguarding sensitive information. News of high-profile data breaches, evolving regulations, and sophisticated cyber threats create a constant hum of anxiety. Yet, beneath the surface headlines, there...

4 Reasons SOC 2 Certification Matters

In a world where data breaches and cyberthreats loom large, ensuring the security of sensitive information has become paramount for businesses. At ANM, we recognized the significance of safeguarding our clients' data and maintaining the highest standards of security,...